What is Logistics and Why Does it Matter for Manufacturing?

Logistics is a process that involves the planning, coordination, and execution of the transportation and storage of goods. It’s important for manufacturers to understand logistics because it can have a big impact on their business. There are many factors to consider when it comes to logistics, such as cost, time, resources, and risk. By understanding logistic, manufacturers can make sure their products get to where they need to go in a safe and timely manner. In this blog post, we will explore what logistics is and why it matters for manufacturing. We will also provide some tips on how manufacturers can improve their own logistic processes.

What Is Logistics?

In its simplest form, logistics is the process of moving materials from one location to another. In the business world, logistics generally refers to the coordination and management of the transportation of goods. This can include everything from raw materials to finished products, as well as packaging and warehousing.

Why does logistics matter for manufacturing? Because a smooth and efficient transportation system is critical for keeping production flowing. disruptions in the supply chain can cause delays and setbacks that can have a ripple effect throughout the entire manufacturing process. That’s why it’s important to partner with a logistic company that has experience in managing transportation for manufacturers. They will be able to help you develop a comprehensive logistic plan that takes into account all of the different elements involved in moving your products from point A to point B.

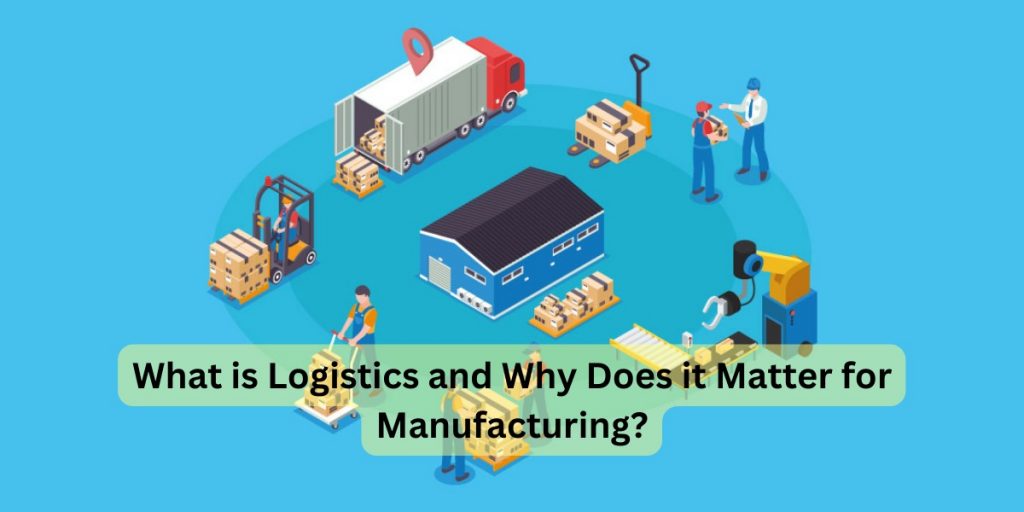

The Role Of Logistics In Manufacturing

In order for manufacturing businesses to run smoothly and efficiently, logistics must be taken into account. It is the process of planning, implementing, and controlling the efficient flow and storage of goods, services, and related information from point of origin to point of consumption. It is a critical part of the supply chain and can make or break a company’s success.

There are many different aspects to consider when it comes to logistics in manufacturing. For example, businesses must decide how they will transport their raw materials and finished products, what type of warehouse or storage facility they will need, how to handle inventory control, and so on. All of these factors must be carefully planned and executed in order to ensure that the manufacturing process runs smoothly.

The role of this in manufacturing is therefore essential in ensuring that goods and materials are moved efficiently throughout the supply chain. By having a well-planned logistics strategy in place, businesses can avoid costly delays and disruptions that can impact their bottom line.

The Benefits Of An Effective Logistics Strategy

An effective logistics strategy can provide many benefits for a manufacturing business, including reducing transportation costs, improving customer satisfaction, and increasing efficiency. Transportation costs can be reduced by consolidating shipments and using efficient routing methods. Customer satisfaction can be improved by ensuring timely delivery of products and providing tracking information. Manufacturing businesses can also increase their efficiency by using Just-In-Time (JIT) inventory methods and integrating their logistics operations with their other business processes.

The Challenges Of Implementing A Logistics Strategy

In any business, there are a number of logistical challenges that must be overcome in order to have a successful operation. In manufacturing, these challenges can be magnified due to the complexities of the production process and the need to manage a large number of moving parts.

An effective logistics strategy must take into account all aspects of the manufacturing process, from raw materials sourcing and procurement to finished goods shipping and distribution. It must also be flexible enough to accommodate changes in demand or production schedules.

Implementing a logistics strategy can be a complex and daunting task, but it is essential for manufacturers who want to remain competitive in today’s marketplace.

How To Overcome These Challenges

There are a number of ways to overcome these challenges:

- Improve communication between the various parties involved in the manufacturing process. This can be done through the use of technology, such as enterprise resource planning (ERP) systems, or by simply ensuring that there is a clear and concise communication plan in place.

- Streamline the manufacturing process itself. This can be achieved through the use of lean manufacturing techniques or by implementing just-in-time production methods.

- Optimize the supply chain. This can be done through the use of supply chain management software or by working with a third-party logistics provider (3PL).

- Invest in training for all employees involved in the manufacturing process. This will ensure that everyone understands their role and how it fits into the bigger picture.

- Focus on continuous improvement. By constantly looking for ways to improve the manufacturing process, companies can overcome any challenges that come their way. Get more category post visit